Features:

1、Single-chip microcomputer control, brushless motor drive, stable operation, low noise, high rotational speed accuracy;

2、 After centrifugation, the centrifuge door lock can be automatically opened by setting, reducing operation steps and facilitating sample taking and placing;

3、All parts in contact with sample volatiles and movable joints are made of 304 stainless steel, which is corrosion-resistant and safe;

4、Fixed angle rotor with airtightness, rotor cover can be opened and closed quickly by patented design, and can be operated with one hand;

5、 Independent exhaust duct, activated carbon sponge adsorption, effectively purifying the discharged air;

6、 Real-time PRM/RCF switching, can directly set centrifugal force for operation, and sound and indicator light prompts during operation and shutdown faults;

7、 Dual self-locking structure and motor, with safety detection reminder for door lock;

8、 Features include door cover, error operation reminder, overspeed, over-temperature, imbalance protection functions, ensuring safety for both people and machines;

9、 Adjustable speed-up and speed-down, preventing re-suspension, protecting sensitive samples, and ensuring centrifugation effect.

Parameters:

Model

T18

Max Capacity

6*100ml

Max Speed

20000rpm

Max RCF

25043Xg

Speed Accuracy

±10r/min

Timer Range

0-99min59s

Accel/Decel Setting

1-9

Noise

≤65dB(A)

Power Supply

AC220 50Hz 10A

Consumption

1000W

Size(L*W*H)mm

490*360*263

Weigh(without rotor)

26kg

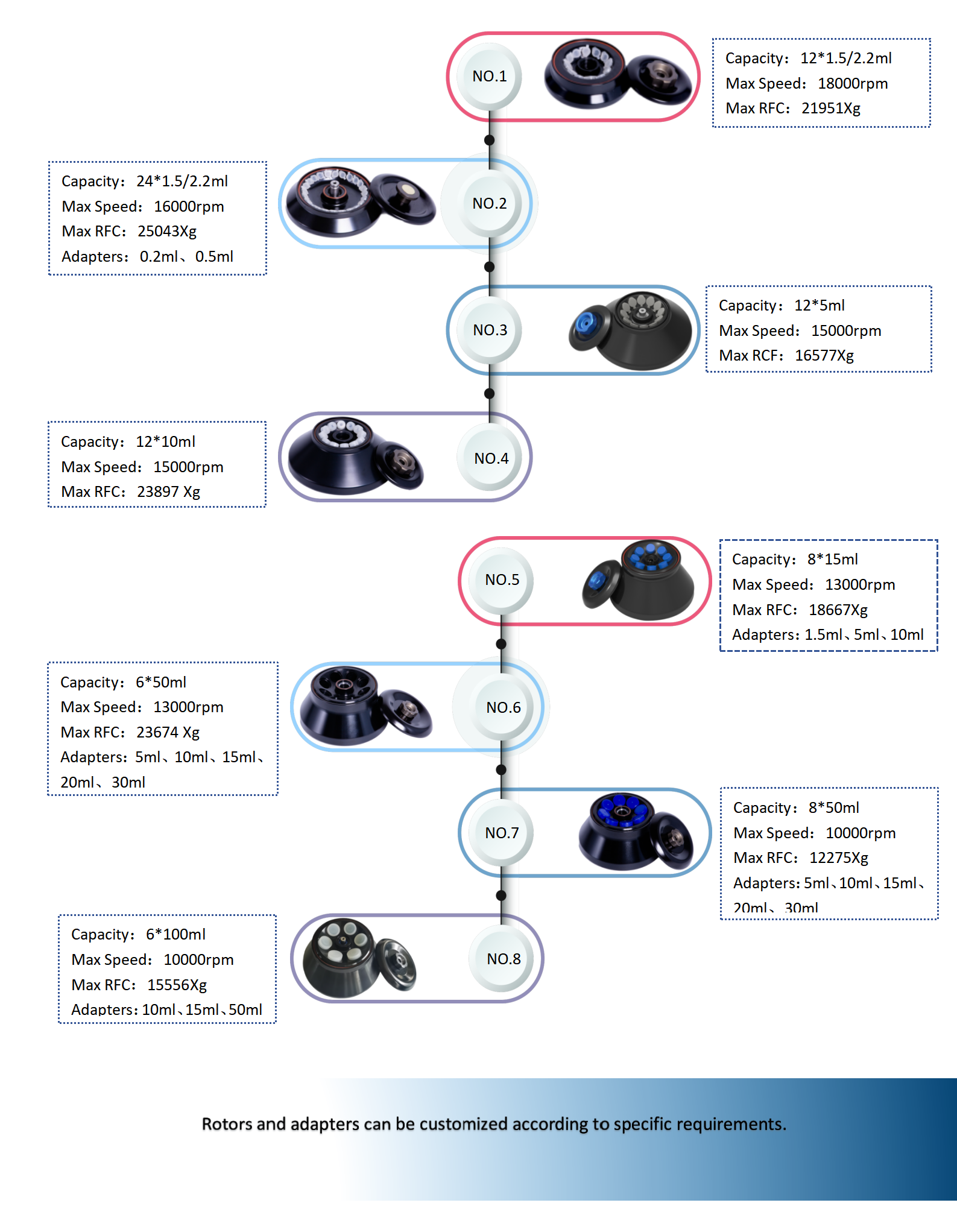

Rotors:

Message success